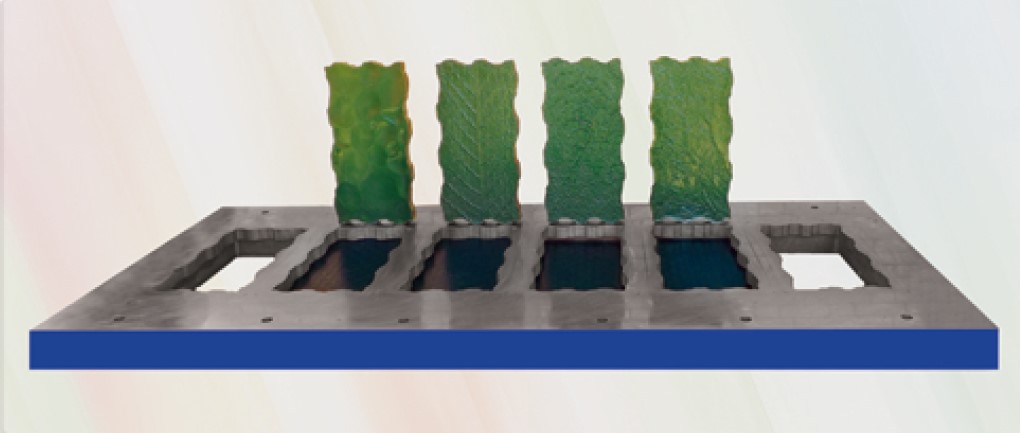

Complete moulds for ceramic industry are being designed, produced in our factory for different types of presses.

Different structure moulds can be produced according to the required ceramic tile design.

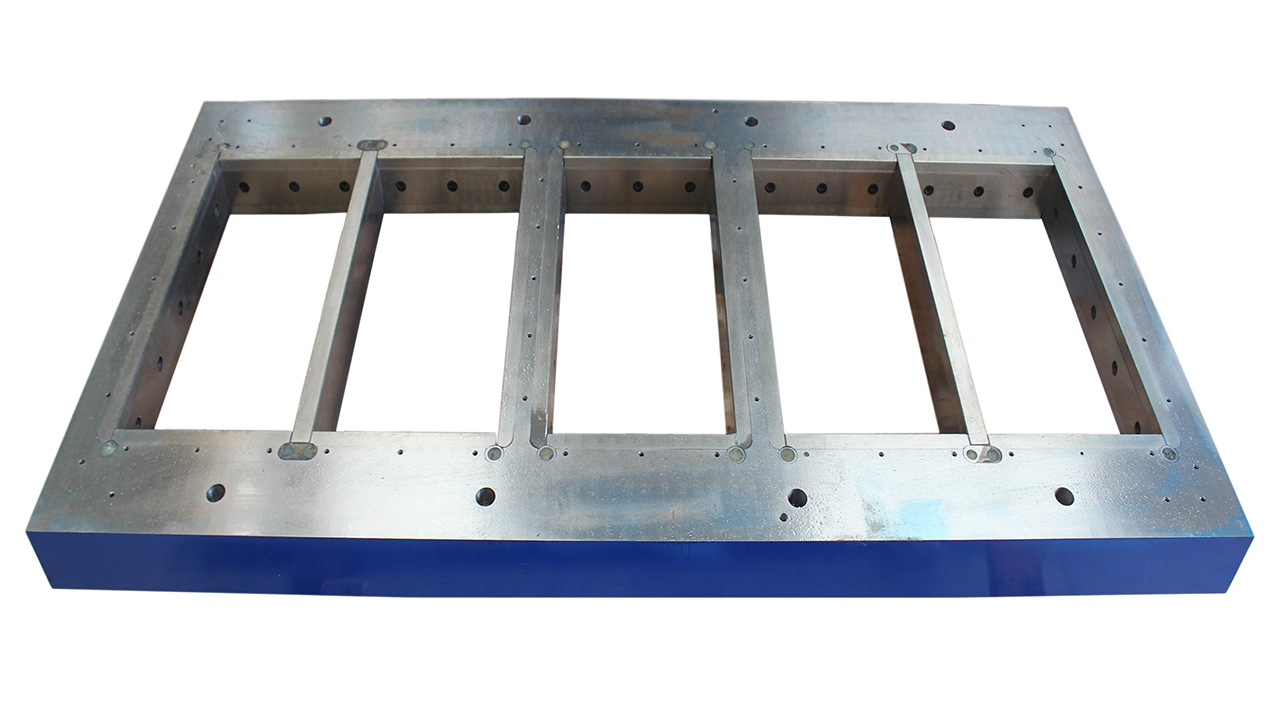

Die box is one of the main components in the mould, Responsible for shaping the tile’s sides and determining its size, Manufactured from C45 material. It has several openings according to the required number of the tiles produced in a single press with consideration to the press’s specific pressure and the tile’s dimensions.

The die box can consist of either:

A single piece die: The die’s cavities are made by a milling machine which gives a non-level surface.

A Two-pieces die: In this case the die’s body is made up of two parts, the lower part has wider openings to allow the seamless movements of the magnetic block and the punches, whereas the upper part is made of many parts that are screwed together to give a high-quality surface and precise dimensions, This type’s characterized by the long service life of the liners but is more costly.

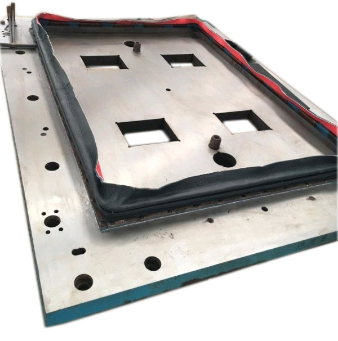

This is the fixed part in the mold which is fastened to the press’s base, contains slots for ventilation, height sensors and pistons, the die box is fastened to it through supporters.

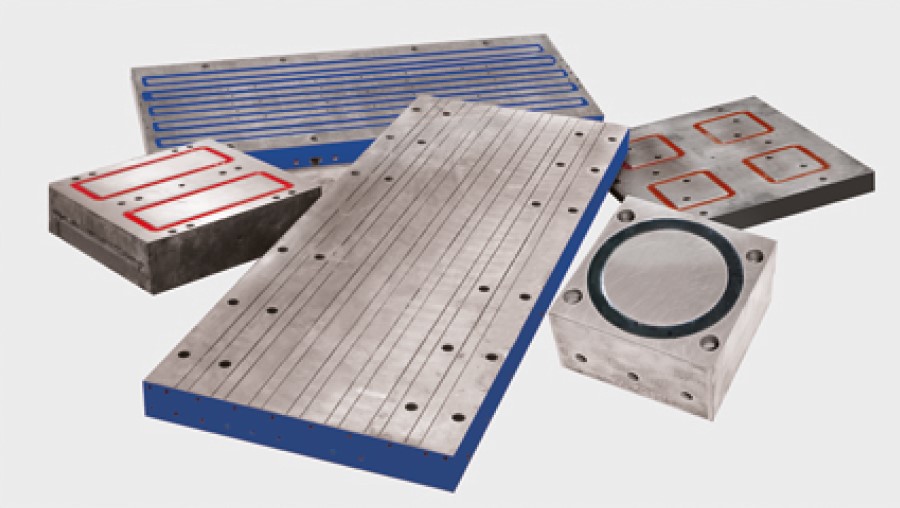

A relatively cheap magnet that requires electricity to operate, can get heated due to electricity running through it, care should be taken as it loses its magnetism during power outage.